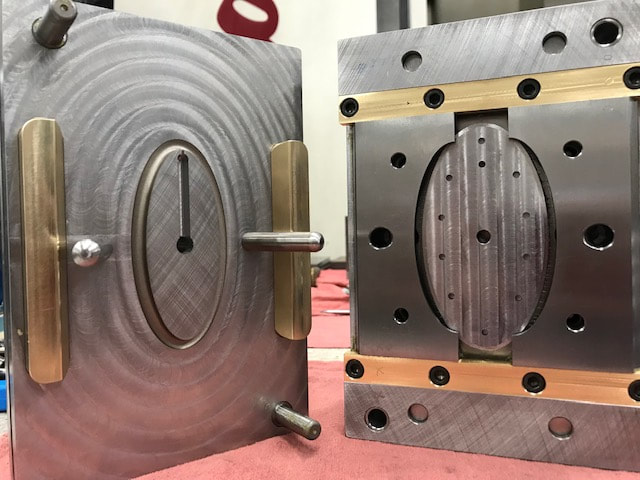

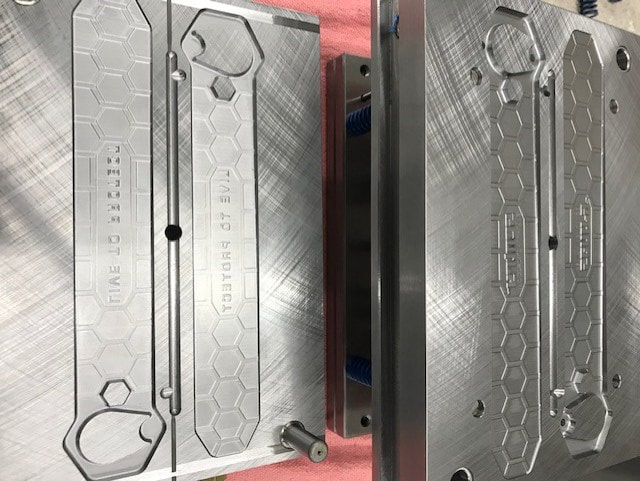

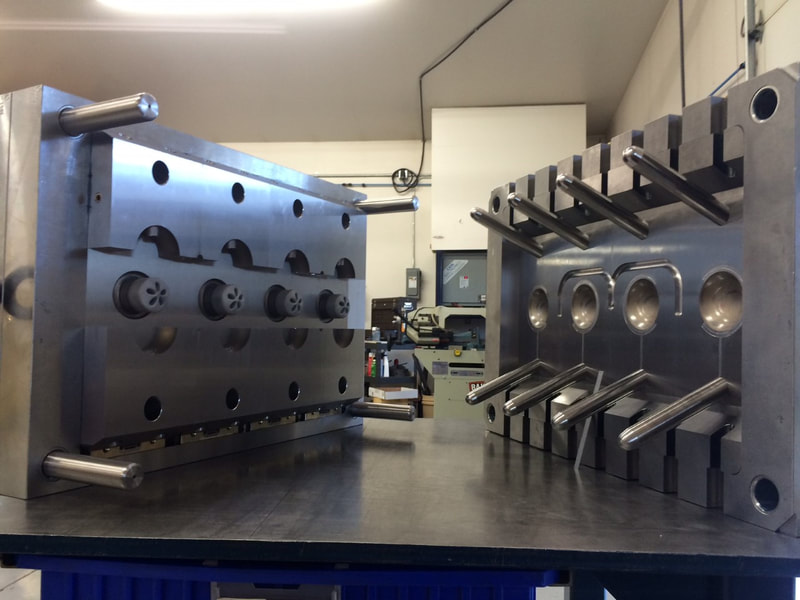

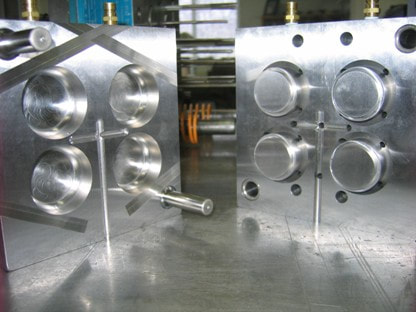

Equipment and capacityWe have all the necessary equipment to build anything from a small mold (such as 5x8) up to a multicavity, 2000 lb mold. Our in-house equipment includes a CNC mill, EDM, multiple surface grinders, manual milling equipment, a cutter grinder, and other general support equipment.

We primarily build pre-hardened steel molds for longer tooling life. Working with this material has proven cost effective and worthwhile for our costumers. |

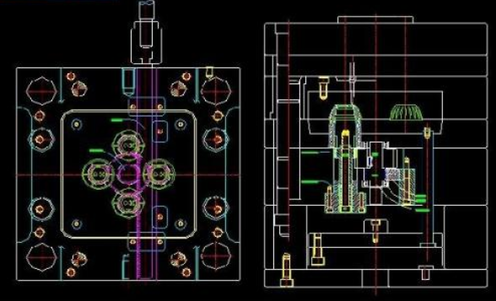

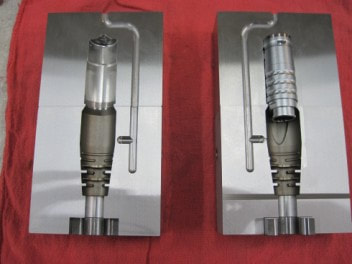

Design to realityMany of our customers bring us a completed part design drawn by in-house engineers. If you don't have a completed design, we can help you streamline your design and turn it into an engineered mold design in CAD.

We also work closely with companies who do prototyping work, so we can assist you in getting a prototype completed to test and refine before we start the mold building process. |